Homepage » Services » Engineering » Simulation & Calculation

BEST POSSIBLE SAFEGUARDING OF FUNCTIONS, MOLDED PARTS AND TOOLS IN THE RUN-UP TO PRODUCTIONWE CALCULATE, SIMULATE AND OPTIMIZE

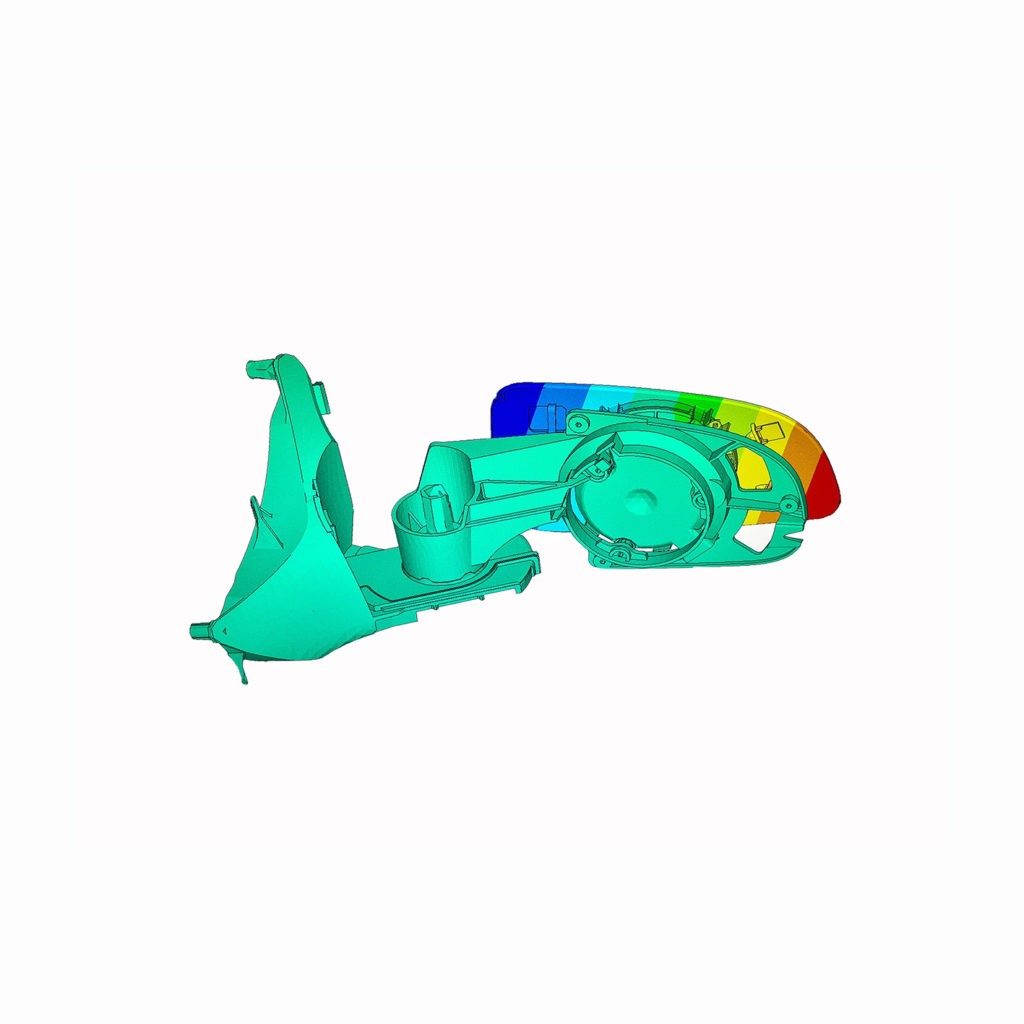

Simulation methods have become an everyday companion for product developers and are indispensable for fast and competent product implementation. The IMPETUS Simulation Center has a wide range of leading simulation software and experienced calculation engineers for rheological, mechanical and thermal molding or mold design. The Plastics Simulation Center is also excellently prepared for all questions that can be solved by means of FEM load calculations, whether static or dynamic in nature, up to and including service life calculations.

Our calculation engineers analyze problems to be expected during subsequent production and product use at a very early stage of development and offer feasible solutions.

THE SIMULATIONS MAKE THE SAFETY

>

INJECTION MOLDING SIMULATION

>

FEM CALCULATIONS (FINITE ELEMENT ANALYSIS)

>

LIFETIME DIMENSIONING

>

TOOLING & COMPONENT MEASUREMENT

>

THERMAL TOOL DIMENSIONING

>

DIMENSIONING TARGETS

SIMULATION OF MANUFACTURING PROCESS AND MOLD

Depending on the problem and the size of the component, we select the optimum calculation programs, analyze weak points in the component, such as weld lines or air inclusions, and optimize sprue positions and sprue type. We also perform variant calculations for large-area and thin-walled components, such as instrument panels, large refuse containers or covers, and minimize warpage. With the help of 3-dimensional filling simulation, we check, among other things, the realization of thick-walled components or those with extreme wall thickness jumps.

In addition to molding design and production optimization, Impetus develops suitable mold concepts. In particular, warpage optimization and thermal tool design have developed strongly in recent years. This can considerably increase the quality of the components and minimize the cycle time.

CORRECTLY ASSESSING COMPONENT LOADS WITH FEM ANALYSEs

In addition to standard calculations of load conditions, deformation situations and failure mechanisms, specialized calculations such as the consideration of anisotropy and time-dependent factors, as in service life design, are among our specialties.

The calculation of the dynamic properties of components (modal analyses) primarily involves the prediction of vibration states under various excitations. Here, too, our experts use the simulation of dynamic assembly behavior to reduce the experimental effort after the model has been created for a group of components and to predict the vibration behavior of similar assemblies.

It is almost always necessary to achieve a development result that satisfies different, usually opposing, optimization specifications. Due to the large number of component optimizations carried out in a wide variety of industries, we are able to deliver results quickly and in a target-oriented manner.

THE IMPETUS SIMULATION CENTER HANDLES THE FOLLOWING TASKS IN PRODUCT AND PROCESS SIMULATION, AMONG OTHERS:

- Parameter optimization (including filling behavior, machine parameters such as temperature distribution, shear stress distribution, filling pressure, cooling time, holding pressure, clamping force)

- Sprue optimization

- Warpage calculation and stress analysis

- Fiber orientations and coupling with FEM

- Mold cooling and design of the temperature control system

- Simulation of near-contour cooling

- 2K injection molding, sandwich injection molding

- GIT, WIT: Determination of fluid penetration depth, residual wall thicknesses, optimization of the number and position of injection needles and the level of gas pressure

THE IMPETUS SIMULATION CENTER CARRIES OUT STRUCTURAL MECHANICS CALCULATIONS/FEM ANALYSES WITH THE FOLLOWING TASKS, AMONG OTHERS:

- linear and non-linear as well as anisotropic problems

- components with contact

- different component variants with regard to agreed optimization targets

- dynamic component design (vibration analysis, modal analysis)

- compression loads

- impact loads

- lifetime prediction (isotropic, anisotropic)

Software Tools

Impetus Plastics Engineering uses CADMOULD, Moldex3D, HYPERMESH, ANSYS and Digimat, among others, for injection molding simulation and the calculation of component loads.

Contact US now

Do you still have questions or requests? Please do not hesitate to call us or write an e-mail.

We look forward to getting to know you better – at any time!