Homepage » Services » Engineering » Development & Construction

DESIGNS WITH PRODUCT-SPECIFIC SOLUTIONS FOR INDIVIDUAL COMPONENTS AND COORDINATED ASSEMBLIES

FREE OF REWORK AND SUITABLE FOR PLASTICS

Product developments are subject to high technical and deadline requirements that can only be met by using state-of-the-art CAD systems. With the design systems, 3D data is made available which is used without reworking, consistent for all development steps right through to toolmaking.

For the engineers at Impetus Plastics Engineering, it is therefore a matter of course that the CAD models take into account draft angles and radii as well as tolerances. From the very beginning, our designers work closely together with the Impetus simulation center to ensure that the designs are always suitable for production and loading. Of course, we have specialists in-house for all important CAD systems.

3D CONSTRUCTIONS MAKE CONTINUITY

>

TOLERANCES

>

INJECTION MOLDING SIMULATION

>

FEM CALCULATIONS (FINITE ELEMENT ANALYSIS)

TOLERANCES SIGNIFICANTLY INFLUENCE COSTS AND DEVELOPMENT TIME

By specifying molding and manufacturing tolerances, the designer significantly influences component costs. This is generally known, yet the influence of the properties and the processing and manufacturing conditions for plastics is often underestimated. In many cases, very tight tolerances are required, which can only be realized with considerable effort and high costs in mold making and component production.

Therefore, the general principle of tolerancing applies: Tolerances should always be set as low as necessary, especially for plastic products!

It is up to the developer to demand lower tolerances only where they are absolutely necessary for the function of the components.

In order to be able to set tolerances sensibly – i.e. economically – the product developer must know the various influencing factors and the effects on them, and evaluate and set them differently depending on the product.

Our designers are therefore also familiar with DIN ISO 20457 and DIN 16742. In addition, we support development projects at IMPETUS holistically and check component dimensions quickly and contact-free by means of optical 3D measurement, among other things.

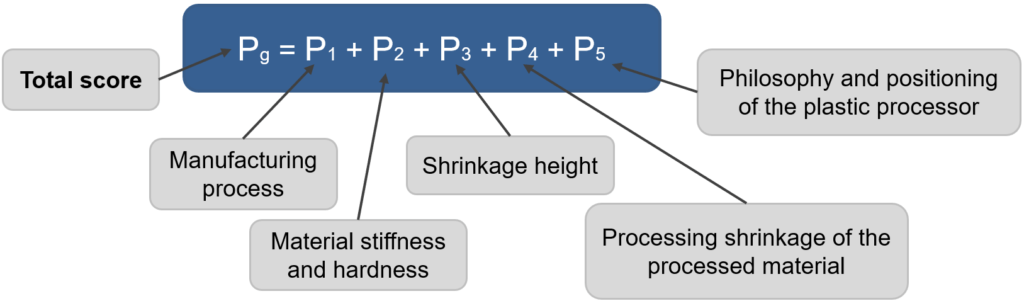

DETERMINATION OF TOLERANCE GROUPS WITH A POINT SYSTEM ACCORDING TO CURRENT TOLERANCE STANDARDS

As an implementation service provider and technical consultant, Impetus Plastics ensures that its customers know what is technologically possible – when it makes sense – and in what time frame when implementing their product idea. IMPETUS ensures that the deadlines are set sensibly and that the cost targets are set and achieved correctly. By using the latest simulation software and the best possible selected test procedures, the quality of the product is optimally adjusted at the same time. In addition, we efficiently use a wide range of risk assessment procedures for risk assessment.

3D CAD DESIGN SOFTWARE

Our design specialists have been working with 3D design systems for many years and will support you at every stage of development and, of course, in series designs.

Impetus has specialists for the following 3D CAD systems:

- PTC Creo Parametrics (Pro/Engineer)

- NX (Unigraphics)

- SolidWorks

- Catia (V5)

- VISI CAD

contact us now

Do you still have questions or requests? Please do not hesitate to call us or write an e-mail.

We look forward to getting to know you better – at any time!